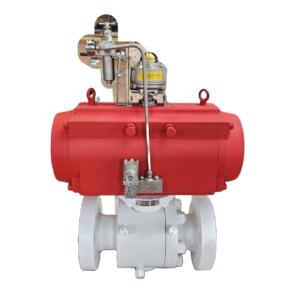

CNG LNG LPG Top entry cryogenic trunnion ball valve

PHOTOS SHOW SPECIFICATIONS AS BELOW:

SIZE: 8″

RATING: 150LB

END: FLANGE AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : A351 CF8M

BALL: ASTM A182 F316+HF

STEM: ASTM A182 F316

SEAT: PCTFE OR HF METAL

ACTUATION: MANUAL AND GEAR

Description

GENERAL

Size: 1/8″~36″.

Pressure Rating: 150LB~4500LB, PN6~PN750

Design Temperature: -196℃~120℃

Design Manufacture Code: ASME B16.34, BS6364, API 608, API 6D,SHELL SPE77/200

Face to Face: ASME B16.10, EN558

Connection: ASME B16.5, B16.47, EN1092, RF/RTJ. ASME B16.25 BW ASME B16.11 SW/NPT ETC.

Trims Design: Floating ball / Trunnion ball

General Applications: CNG,LNG,LPG, CO2,N2 ETC.

Safety Design: anti-blow out stem, fire proof, anti-static

Special Test if Required: Low Emission, DNV/BV/SGS TPI service is available.

MAIN TYPICAL MATERIALS LIST

BODY: ASTM A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, MONEL K400/K500, H-276

BALL: ASTM A182 F304/F316/F51/F53/F55,MONEL K400/K500, H-276 hardened

EXTENDED BONNET: ASTM A351 CF8/CF8M, ASTM A182 F304/F316

STEM: F304,F316,XM-19, 17-4PH, INCONEL 718, MONEL K-500

SEAT: SPRING ENERGIZED PCTFE, PEEK OR HF METAL

OPERATOR: LEVER OR GEAR OR ACTUATOR

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D.BS6364

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.